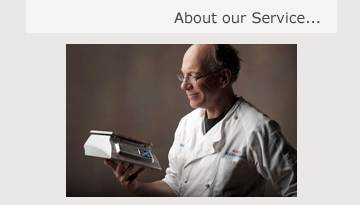

Data Instruments & Vithayathil Trading Corporation

- We are one of the Leading Dealer for sales & service of World class Electronic Balance (Mettler Toledo Swiss), Currency counter cum super fake note detector, paper sherdder and Electronic Moving Message Display .

- Last 24 years our Presence in south India specially Kerala & Tamilnadu

- Our success so far is chiefly attributed to excellent service back-up which could to testified by our 8400 customers gathered with in a span of 24years.

- We operate with structured network through a battery of 8 sales executives, 6Service engineers & 4 office staff.

- Office & service center is Located in the very heart of Thrissur Town & geared up with modern amenity

- We have professionally trained and qualified Engineers to offer excellent service back up in the warranty period& even after wards.

- We being constantly in touch with all relative circles in weighing and other products as well as in Kerala have Hall marking Centers, Diamond & Gold Jewellery showrooms, fire assay testing Centers, Manufacturing Units, Die works, Whole sale Division, Lab, Bank, Real Estate, Hospital, Educational, Hotels, Vehicles, Home appliances, Hard ware, Sanitary wares, Building materials Pharmaceutical Distributors, Silks& Retail Sector.

- Do things with love; you will achieve success!

- We can always earn money; but can never create time; please do not Waste time.

History of Mettler Toledo Swiss

Swiss Precision Instruments Become Global

Our laboratory instruments are the foundation of labs all over the world, as they improve processes in research and development,d rug discovery and quality control.

Our industrial instruments and software optimize operations from receiving to shipping, with solutions for production, end-of-line product inspection and logistics.

Our retail solutions manage fresh foods from inventory and merchandising to maximize efficiency and profitability.

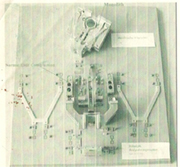

The MonoBloc weighing cell: more than one step ahead of the competition

METTLER TOLEDO has often set milestones in weighing technology: with the first electronic analytical balance, with the fully automatic adjustment proFACT, with the rugged microbalance, with the simple operation via SmartBar – and now once again with a revolutionary weighing cell called MonoBloc.

Highly resilient

MonoBloc is a high-performance weighing cell. The entire structure of the weighing cell is spark-eroded from a single aluminum alloy workpiece using innovative electrical discharge wire cutting (wire-EDM). The same alloy is used in the aircraft industry for highly stressed parts, so you can be sure of a long service life and extreme ruggedness.

Highly resilient

Parallel guidance, link, hanger, and up to three transmission levers are integrated into the MonoBloc. This reduces the number of components and moving parts by more than 50 percent and further improves the already legendary dependability of METTLER TOLEDO balances.

Highly precise

The two-dimen-sional structure distinguishes the MonoBloc from conventional weighing cells. This construction prevents stresses and torsion forces acting on the mechanical parts. The result: extremely high measurement precision, no matter how heavy you load the balance

Beneficial

Compared with conventional technologies, such as milling, the METTLER TOLEDO wire-EDM technology offers the following advantages:

- Higher manufacturing precision - 0.1µm compared with 0.4µm cutting accuracy.

- Constant manufacturing quality, as the moving wire is continuously renewed in the electrodischarge machining of each MonoBloc. In contrast to a milling head, there is no wear.

- Higher resolution - 20 million digits compared with 8 million digits.

Tangible benefits

The MonoBloc construction provides:

- Fewer moving parts

- Less material waste

- Rugged construction

- Dependable measurements for years

- Extremely high precision – day in, day out

- Increased productivity

- Reduced downtime

METTLER TOLEDO Turing Softwares

Press Release

Acquisition of Safeline Limited

Mettler-Toledo Holding, Inc. (OTC: METTOL) announced today that it has acquired Safeline Limited. Safeline, based in Manchester, U.K., is the world’s leading supplier of metal detection systems. Metal detectors are an integral part of the safety and quality control efforts of companies who produce and package goods in the food, pharmaceutical, cosmetics, chemicals and other industries. The company has reported sales of GBP 28.6 million (USD 46.4 million) and operating profits before non-recurring costs of GBP 6.7 million (USD 11.0 million) for its fiscal year ended March 31, 1997.

The acquisition of Safeline, when combined with METTLER TOLEDO’s market leading product lines will anchor the Company’s sales to industrial markets in the high-growth, high-margin quality control applications segment. Together with Safeline, METTLER TOLEDO will provide integrated solutions for product quality data management and statistical process control for the production, filling and packaging applications of its customers.

Robert F. Spoerry, Chief Executive Officer of METTLER TOLEDO, stated, "This acquisition supports the Company’s strategy to offer comprehensive solutions for our customers by selectively investing in related technologies. We are convinced that our customers will look favorably on this combination which brings together the market leading technologies of Safeline’s metal detection systems with our own market leading industrial product lines. Our customers will benefit from integrated solutions which will improve the efficiency of their processes and increase product quality and safety."

"We are also pleased to announce that the entire executive team at Safeline has agreed to stay with the company. We welcome the employees of Safeline to the METTLER TOLEDO family", said Mr. Spoerry.

METTLER TOLEDO also announced the completion of a new credit facility to acquire Safeline and refinance its existing bank debt. The Company disclosed that the new facility provides for interest rates substantially below the existing facility. "The new credit facility demonstrates the confidence the financial community has placed in our company and its employees. We are especially pleased that this could be accomplished so soon after our employee buy-out sponsored by AEA investors, and in conjunction with a significant investment such as Safeline," said Mr. Spoerry in closing. The Company also reported that it would record a non-cash extraordinary charge for the quarter ended June 30, 1997 to write-off financing costs associated with its previous credit facility. In addition, the Company disclosed that it expected to record additional charges in 1997, primarily non-cash, for purchase accounting and other acquisition related items. The amounts associated with these charges have not been determined but the Company expects only the non-cash charges to be significant.

METTLER TOLEDO is the world’s largest manufacturer and marketer of weighing instruments for use in laboratory, industrial and food retailing applications and a leading provider of related laboratory analytical instruments. The company focuses on the high value-added segments of the weighing instruments market by providing solutions for specific applications. METTLER TOLEDO, which became an independent company through an employee buy-out sponsored by AEA Investors Inc., New York (NY) in October 1996, services a worldwide customer base in over one hundred countries primarily through wholly-owned subsidiaries, and includes manufacturing sites in the United States, Asia and Europe. The Company has annual revenues of approximately $900 million and more than 6’000 employees worldwide. Its Senior Subordinated Notes are traded "over the counter" in the United States under the symbol "METTOL".

Contact: William P. Donnelly, Chief Financial Officer

Phone: +41 1 944 2262

Fax: +41 1 944 3150

Dr. Erhard Mettler, a Swiss engineer, started a precision mechanics company in Küsnacht, Switzerland.He invented the substitution principle with a single-pan balance, capable of being produced in series. Analytical balances with a single weighing pan gradually replaced conventional two-pan balances in the laboratory. METTLER TOLEDO was sold by Ciba-Geigy AG to the New York-based AEA Investors Inc., in preparation for a subsequent initial public offering. We completed our initial public offering and began trading on the New York Stock Exchange

The measurement of up to one ten-millionth of a gram became possible. "The Mettler Balance" proved to be a catchphrase in the laboratory. Consequently, with the advancement of microprocessor technology, various new applications broadened our field of activity. Successive innovations led to a wide range of products for the laboratory, like automated titrators and thermal analyzers, and also to various products for customers in the manufacturing industries. Simultaneously, our sales and service network was further expanded on a global basis.

The company known as Mettler Instrumente AG introduced the first-ever fully electronic precision balance, the PT1200. This model was the first electronic balance in the world to be awarded official certification in the highest class of accuracy (Class 1). It marked the beginning of the electronic age.

Mettler-Toledo International, Inc

METTLER TOLEDO is a global manufacturer and marketer of precision instruments for use in laboratory, industrial and food retailing applications. The Company has strong worldwide leadership positions. A significant majority of our instrument sales are in segments in which we are the global leader. In addition to a broad product offering, we have one of the largest global sales and service organizations among precision instrument companies.

We focus on the high value-added segments of our markets by providing innovative instruments that often integrate various technologies including application-specific solutions for customers. We design our instruments not only to gather valuable data but also to facilitate the processing and transfer of this data into customers' management information systems.

Mettler-Toledo (NYSE: MTD) is a global manufacturer of scales and analytical instruments. Mettler Toledo is the brand name whereas Mettler-Toledo (with dash) is the name of the company. The company consists of several operating divisions in North America and Europe. Mettler-Toledo specializes in the area of precision instruments for professional use. Mettler-Toledo laboratory instruments are used in research, scientific, drug discovery, and quality control labs, amongst many others in the pharmaceutical, chemical, food and cosmetics industries.

Formation and History

Mettler-Toledo was formed in 1989 by the merging of two companies: Mettler, based in Switzerland, and Toledo Scale, based in Columbus, Ohio, USA.

In 1945, Dr. Erhard Mettler, a Swiss engineer, started a precision mechanics company in Küsnacht, Switzerland. He invented the substitution principle with a single-pan balance, capable of being produced in series. Analytical balances with a single weighing pan gradually replaced conventional two-pan balances in the laboratory.

In 1980, Dr. Mettler sold his business to Ciba-Geigy AG. A third pillar - after laboratory and industrial - was created: the retail business. Technological progress had made it possible to advance retail scales to instruments for the management of perishable goods.

In 1989, METTLER acquired TOLEDO Scale Corporation, the largest US manufacturer of industrial and retail scales based in Columbus, Ohio. Its founder, Henry Theobald, had launched an innovative store scale with an automatic weight and price display in 1901.

In 1996/97, Mettler-Toledo was sold by Ciba-Geigy AG to the New York-based AEA Investors Inc., in preparation for a subsequent initial public offering. The initial public offering was completed and began trading on the New York Stock Exchange, under the ticker symbol MTD. The company has grown both organically and through the acquisition of several companies to the current size of 10,000 employees and revenues of USD 2 billion (2008).

Operational Structure

Mettler-Toledo is a global manufacturer and marketer of precision instruments for use in laboratory, industrial and food retailing applications. They are geographically diversified with sales in 2012 derived 34% from Europe, 34% from the Americas and 32% from Asia and other countries. The Company has an extensive global sales and service organizations with approximately 6,000, or approximately one-half, of the employees providing sales and service in 36 countries. The Company has a manufacturing presence in Europe, the United States and China.

Laboratory

1952, the measurement of up to one ten-millionth of a gram became possible with the laboratory balance products. "The Mettler Balance" proved to be a catchphrase in the laboratory.[citation needed] Consequently, with the advancement of microprocessor technology over the years, a wide range of products for the laboratory were invented, like automatedtitrators and thermal analyzers. Mettler-Toledo laboratory products and technology were able to improve processes in research and development, drug discovery and quality control. Application-specific software for balances provides data analysis opportunities to enhance accuracy, productivity and compliance.

RAININ Instrument

In 2001, Mettler-Toledo purchase Rainin Instrument, LLC, which is now a wholly owned subsidiary of Mettler-Toledo.[3]Rainin supplies precision instruments and services worldwide. Rainin pipettes provides automated chemistry systems used in drug and chemical compound discovery and development. The company also manufacturers and marketers metal detection and other end-of-line inspection systems used in production and packaging.

AutoChem

Industrial

The Company manufactures numerous industrial weighing instruments and related terminals and offer software for the pharmaceutical, chemical, food and other industries. In addition, it manufactures metal detection and other end-of-line product inspection systems used in production and packaging. The Company supplies automatic identification and data capture solutions, which integrate in-motion weighing, dimensioning and identification technologies for transport, shipping and logistics customers. The Company also offers heavy industrial scales and related software.

Cargoscan

Mettler-Toledo Cargoscan Dimensioning solutions are used by international transport companies, small carriers, warehouses and distribution centres around the world. Systems are all approved according to international weights and measures standards, ensuring high instrument performance. It has been shown that laser range finder technology provides high accuracy in the industry making an impact on a production's revenue

Retail

Mettler-Toledo offers

THORNTON

Thornton, Inc. Process Analytics Division [4] founded in 1964 develops, manufactures, markets, and supplies instrumentation and sensors used for liquid process measurement and control applications.The instrumentation provides pure water treatment measurement & control for the pharmaceutical industry; and parameters of conductivity/resistivity, TOC, pH, DO, dissolved ozone and flow for the semiconductor and power industries.

INGOLD

Founded in 1948, INGOLD specializes in solutions for pH, DO, conductivity, turbidity and CO2 for process analytics applications in chemical, pharmaceutical and food & beverage industries.

Hi-Speed

Hi-Speed division joined Mettler-Toledo in 1981 to provide weighing solutions for laboratory, industrial, and food retailing applications. The Product Inspection Team provides the checkweighers, metal detection devices, and other end-of-line inspection systems for local and multinational companies worldwide

Safeline

Safeline was developed in 1989 at METTLER TOLEDO. The Safeline product was an advanced metal detector the used digital technology for increased sensitivity and accuracy.

To expand the detection solutions, METTLER TOLEDO acquired Raytech in 1997. Raytech manufactured x-ray inspection equipment. The x-ray inspection equipment combined with the detection products allowed companies to identify multiple contaminants as well as verifying product integrity and portion control.

CI-VISION

Mettler-Toledo CI-Vision is a wholly owned subsidiary of Mettler-Toledo Inc. The Mettler-Toledo Product Inspection Group, consisting of CI-Vision, Hi-Speed and Safeline, is a superior supplier of in-line checkweighers, metal detectors, machine vision systems and x-ray inspection systems.

Charitable Contributions

Mettler-Toledo actively participates in the United Way organization.The company offers employees opportunities to contribute financially or by supporting volunteer activity during paid company hours.

Mettler-Toledo

Based in Switzerland and in the USA registered Group Mettler-Toledo specializes in precision balances for professional use. Thecompany is the world's largest manufacturer of weighing systems , covering a weighing range of 0.0000001 grams to 1000 tons. The offering includes analytical instruments, systems for automated drug research and drug development, tools for process analysis and control systems for the packaging industry , available in more than 100 countries.

Mettler-Toledo employs about 12,000 people and generated sales of 2.342 billion U.S. dollars in fiscal year 2012. In 2010, Mettler-Toledo scored 37% of its sales in Europe. 36% came from the Americas, 27% to Asia and other regions. The shares of the company are traded on the New York Stock Exchange traded.

History

In 1945, the Swiss engineer Erhard Mettler in Küsnacht on Lake Zurich , a precision engineering company. He used the substitution principle and developed a single-pan balance for series production. In the single-laboratory analytical balance gradually displaced the conventional two-shell scale . In the fifties, measurements were performed on a ten millionth of a gram exactly possible. 1973 launched the Mettler Instrumente AG, a first fully electronic precision balance, the PT1200. This model was the world's first electronic balance, which for the highest accuracy class (class I) was approved. Innovation brought a wide plethora of laboratory equipment - including automatic titrator and thermal analysis shows as well as various products for the industry - devices. In the 1980s came with the retail division in addition to the laboratory and industrial area a third pillar. Technological advances made it possible to make retail scales systems for the management of fresh produce. In 1980 Mettler sold his company to the Ciba-Geigy AG.

1989 Mettler Toledo Scale Corporation was acquired, the largest American manufacturer of industrial scales, based inColumbus , Ohio . Its founder, Henry Theobald had, in 1901 launched a retail scale with automatic weight and price display on the market. From the forces of the two companies emerged Mettler-Toledo. In October 1996, Mettler-Toledo was sold by the Ciba-Geigy AG to New York AEA Investors Inc., in preparation for the planned IPO. On November 14, 1997, the company completed the first mission. Its shares have since been on the New York Stock Exchange traded under the ticker symbol MTD.

Organization

The company is headquartered in Delaware registered in the United States and headquartered however in Greifensee inSwitzerland . While the stock market activities of the United States are directed from, operates out of the management of the Switzerland. This is due to 1991 the merger between Mettler and Toledo materialize.

The sales organization for Germany is located in casting and dates back to 1957, when bought by Mettler balances firm Spoerhase. The company is the world's largest supplier of the three most commonly used laboratory instruments -balances , pipettes , and pH meters.

Mettler-Toledo Instruments are in the research and development, including drug discovery, in use as well as in quality control including the pharmaceutical, chemical -, food and cosmetics industries.

About Sartorius

Florenz Sartorius, a mechanical engineer at the University of Goettingen in Germany, founded Sartorius in 1870. Sartorius worked together with Friedrich Woehler, the discoverer of aluminum to develop the first' short beam balance with magnificent specifications in speed and accuracy unequalled by any other weighing instrument in those times. This cooperation with the University continued and in 1927 technical collaboration with the 'Nobel Prize winner Prof. Richard Zsigmondy resulted in the first commercially produced membrane filters in the world. The trend continued with many firsts in development and innovations.

Florenz Sartorius, a mechanical engineer at the University of Goettingen in Germany, founded Sartorius in 1870. Sartorius worked together with Friedrich Woehler, the discoverer of aluminum to develop the first' short beam balance with magnificent specifications in speed and accuracy unequalled by any other weighing instrument in those times. This cooperation with the University continued and in 1927 technical collaboration with the 'Nobel Prize winner Prof. Richard Zsigmondy resulted in the first commercially produced membrane filters in the world. The trend continued with many firsts in development and innovations.

Today Sartorius is an independent international group, officially listed on the stock exchange in Frankfurt. It comprises over 30 companies and has more than 3,500 employees, with a worldwide presence through affiliates and agencies Head quartered in terms of factory facilities, sales and administration in Goettingen, Germany, where the company was founded, it has production facilities in other locations (America, Europe and Asia including India and China].

The firm ranks among the leaders internationally in the Fields of Mechatronics, Biotechnology and Environment Technology . Sartorius 142 years experience or being the global leader in weighing technology IS manifested in its Mechatronics business worldwide where it has an interdisciplinary combination of mechanical, electronics enginrering and information technology.

Its Biotechnology business covers applications for biomolecular and microbial separations, concentration, purification, fermentation and cell culturing.

Sartorius is increasingIy focusing on the customer's chain of processes with its broad range of products for laboratory and industrial weighing, including electrochemistry.

Since 1992, Sartorius has been accredited for compliance with ISO 9001 and 14001 apart from, various certifications like TUV, DIN, EIN, PTB, OIML, DKD, etc. Moreover, Sartorius is a recognized member of various certification and calibration networks. Sartorius Mechatronics technoiogy is used as reference and for Analysis in all the large Weights and Measures laboratories around the world.

About Sartorius Weighing Technology

The Monolithic Weighing System

- Systematic use of "high-speed- cutting" technology

- Complete weighing system is cut from a compact block of aluminium alloy

- Minimized combination of different materials

- All "system-components" are manufactured from the same material

- This minimizes the balance's thermal sensitivity, which can be observed in conventional balances

- The special aluminium alloy features extremely high mechanical stability

- Mechanically rugged weighing system for daily use

- Failure rate <0:1% - High degree of integration

- With number of parts reduced by 70%.

- Reduces the interfering effects of different material.

- Reduces the number of contact surfaces.

- Reduces the fluctuations in accuracy involved in calibration / adjustment.

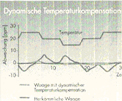

- Less sensitive to fluctuations in temperature

- Excellent metrological specifications

- Full resolution of 0.01mg to capacity 210g

- Full resolution Of 0.1g up to 64,000 g

- Amazing Short response times < 1.5s and high reproducibility - Systematic use of “High -speed-cutting” technology

- Complete weighing system is cut from a compact block of aluminium alloy

- Minimized combination of different materials

- All "system-components’ are manufactured from the same material.

- This minimizes the balance's thermal sensitivity, which can be observed in conventional balances

- The special aluminum alloy features extremely high mechanical stability

Innovative weighing technology for enhanced reliability

- High mechanical stability -rugged for daily use

- High degree of integration = few parts =less probability of failure

- Less sensitive to fluctuations in temperature

- Excellent specifications and amazing short response times

Gold and Carat Scales

Top quality -proven Sartorius value for your money:-

Being able to trust the accuracy of weight readouts is still the measure of all things.The name Sartorius stands for the highest level of reliability for weighing accuracy - without any compromises - with all the performance features that you need in your business and you've come to expect from Sartorius. Options include scales that are verifiable for use in legal metrology within the EU and their Signatory States, and OIML Certificates of Conformity for R76-1.

The High Standard range – real “gems” for weighing gold and gemstones :-

Automatic, anti-glare readouts :

Blue is cool, a color that refreshes. Just one glance at the blue, backlit display, and you'll agree. It enables error-free reading under any lighting conditions. Without any waiting. Just place your precious metal or gem sample on the pan, and the exact, stable readout will appear instantly.

Weigh in any unit of mass :

Blue is cool, a color that refreshes. Just one glance at the blue, backlit display, and you'll agree. It enables error-free reading under any lighting conditions. Without any waiting. Just place your precious metal or gem sample on the pan, and the exact, stable readout will appear instantly.

The High Standard series offers a wide selection of scales that are verifiable for use in legal metrology within the EU and their Signatory States. Plus they have OIML Certificates of Conformity for R76-1.

Nice Price series-no tolerance in weighing and gold and gemstones

Low space requirements

The compact housing dimensions and the light weight of the scale itself enable you to be flexible in setting it up. As a result, the scale offers ideal portability, especially for battery operation.

Fast resuIts

The response time of the scale is so fast that when you load a sample, the stable readout appears nearly simultaneously.

Easy to read

The black-and-white liquid crystal display shows readouts with big, bold and bright digits - in grams, carats, troy ounces, taels or pennyweights. Plus, the display control panel makes operation exceptionally easy.

Nice Price Series-no tolerance in weighing gold and gemstones

Battery-operable as an option

If you are on the move and need to work independently of an AC outlet, you can use a commercially available 9-volt battery in some of our models. All other models are battery-operable when connected to an external rechargeable battery pack.

Logging capability for weighing data

The standard RS-232C serial port allows you to connect a Sartorius data printer to the scale or use the SartoConnect data transfer software to transmit data to a PC.This means you can log all weighing results quickly and reliably, and conveniently recall and print them out as proof, at one touch of the print key.

Fast and reliable counts

Every Sartorius gold and carat scale features a built-in program for counting of the tiniest of parts.

Extensive offer of accessories

A glance at our offer of accessories will show how you can use the capabilities of Sartorius gold and carat scales even more efficiently.

The High Standard range – real “gems” for weighing gold and gemstones :-

Enhanced performance specifications included

The scales' full resolution ranging from 0.001 ct to 1,600 ct enable you to check gemstones more precisely and reliably than ever before.

The extra-large weighing pan and logical operator guidance features make the scale yet even easier to operate than you've come to expect.

The CEmark gives peace of mind knowing that the scale complies with electromagnetic compatibility requirements.

Fast and reliable counts

Every Sartorius gold and carat scale features a built-in program for incredibly fast, easy and error-free counting of the tiniest of parts, such as chain links or facets.

ISO compliance

Maximum reliability - all carat scales (except for GC2502)and all stamp approved gold scales have internal, motorized calibration and adjustment weights. So a touch of the CAL key is all it takes to ensure that your scale operates with the highest accuracy anytime, anywhere. With an optional printer connected to your scale, you can prove in black and white that you work in compliance with ISO at all times. And if you'd like to streamline your sophisticated tasks even more, just take a look at our list of convenient accessories.

By Introducing Monolithic Technology, Sartorius highlighted a technological advance in its communications and literature, a first again since the new MCI microprocessor technology. What first looked like an isolated, but successful advertising campaign for an internationally unique technology offering clear user benefits?

Monolithic Technology offers its users the following benefits: -

- A highly compact weighing system, with the number of individual parts reduced by approx. 70%, this considerably reduces the interfering effects of different materials, the number of contact surfaces, and the normal fluctuations in accuracy which are involved in calibration /adjustment. As a logical consequence, monolithic balances are much less sensitive to fluctuations in temperature, and the variation in their technical specifications, which is common for conventionally manufactured balances, can hardly be detected.

- A mechanically rugged weighing system that has passed the litmus test in thousands upon thousands of our balances long ago. Considering the length of time during which we have been marketing the monolithic system, its failure rate is in the range of 0.1%, well below the data limits complied so far.

- Excellent meteorological specifications that remain at an absolutely constant level down to a readability of 10 mg . Objectively irrefutable, independent, meteorological tests carried out for certification of monolithic balances as legal for trade, our.worldwide service organization, and $e most critical partners of all, our customers, have verified these specifications.

MONOBLOCK

Unlike our monolithic system, the monoblock is machined only on two levels; therefore it has an integration rate only 50%. You can easily feel that more assembly work involved in the MONOBLOCK system just by the look and feel of it. However, our competitors copies our technical points, which we used as unique technical supremacy for launch of our monolithic system, even though monoblock system is by far less technologically sophisticated than SARTORIUS's.

So far, the monoblock is offered with a readability that only goes as far as O.lmg. This limit is certainly not due to a strategic marketing decision, because competitors would certainly want to use the potential for cutting manufacturing costs.

Summary: If all aspects are considered, our monolithic technology has no equal on the market. It is the systematic, constructive implementation of our knowledge that the effects of physical interference can be considerably reduced by utilization our technology for reliable reproducible and consistent measurement. We have good reasons to be proud of Sartorius technological achievement.

Why are we better? Here's an overview of our selling points: -

- Our Monolithic and double lever system have a higher degree of integration. Based on these technologies, all parts that affect the metrological performance of a balance are made of the same material and connected to one another without any so-called parting planes (contact surfaces). Therefore, we have fully met the user's demand for balances that are not susceptible to the interfering effects of ambient conditions.

- As part of our standard product line, we have been offering a monolithic system with a readability of 10 mg for years, and this system has been used with greater success so far. This is convincing proof of the metrological performance capability provided by our technology.

- Monolithic technology guarantees reliability and durability over the years. Our100% traceable service and maintenance records on thousands of monolithic balances. Impressively prove our claim.

- Balances with monolithic weighing technology feature extremely fast response times and high reproducibility. It is easy to prove this claim by making a head to head compression with similar products.

- We have professionally trained and qualified Engineers to offer excellent service back up in the warranty period& even after wards.

- We provide a good service Facilities in South India specially Kerala & Tamilnadu.

- After Warranty period We are providing Either On site Annual maintenance contract/Service (Customer can choose either AMC/service) .